Car Project - part 0.5

Yeah, I broke it. But then I fixed it using technology.

Background

I recently bought an RC drift car to try to make it smarter. Having received it I decided I ought to play with it a bit before turning it into something completely different. Then I broke it.

The issue

I think the problem is that lots of the plastics in the Mission-D RC car are quite mellow. While test drifting the car I must have put too much throttle at some point, deforming a piece that was transmitting torque from the drive train to the wheel.

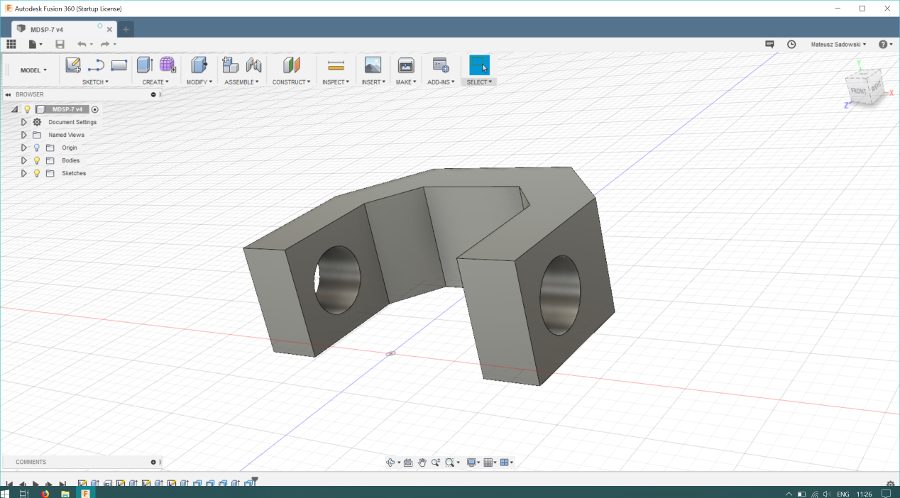

The problematic part is called MDSP-7. I don’t know if you can find it online but surely you can print it:

The print part of this little guy took stunning 3 minutes on my 3D printer (with all the quality settings maxed up). The final result is quite OK and after assembly it seems to be working well:

Going forward

I promise not to break this thing again. Next thing I’ll focus on is creating a base plate to comfortably fir some components on the car. Once I make it I will post an update and a link to an stl file so that you can print it yourself.